Plastics processing enterprises are always on the lookout for ways to optimize energy use, including for injection moulding tool components, such as hot runner systems. A way to increase energy efficiency four fold is a Günther Hot Runner Technology thick-film solution.

Some 66 percent of the electric power used in typical injection moulding operations is fed to production lines. The compressed air supply, the drying process to pretreat granulates and refrigeration to cool down moulds and machines all consume a share of resources. Electric Injection

How can energy use be optimized? Many will immediately think of electrically powered systems, which consume almost 80 percent of the total electricity used in trade and industry. Injection moulding machines offer great savings potential with the use of what are known as fully electric or electromechanical drives. However, it is also worth taking a look at current developments in mould technology and their individual components. Due to the increasing variety of production processes, the requirements for injection moulds are also rising, which further increases their complexity.

Günther Hot Runner Technology has given great thought to the topic of efficiency and made a name for itself as a pioneer early in the game. The expert in hot and cold runner technology launched a revolutionary, high-performance, energy-efficient nozzle system at K 2010 in Düsseldorf over a decade ago. Siegrid Sommer, Managing Director at Günther, described the development of this energy-efficient nozzle technology based on thick film technology as follows at the time: “The Blue Flow thick-film heater for hot runner nozzles took ten years of intensive research and development to create. With thick film technology used as standard in hot runner nozzles, we have managed to create something that provides a more compact, more energy-efficient hot runner design and exploits not insignificant energy efficiency potentials.”

Compared to conventional brass bodies, thick-film heating elements are much finer and have a smaller diameter. Around a mere 20 µm thick, the heat conductors can be attached much more closely and also on a more customized basis per tempering zone thanks to the thick film technology. Consequently, temperature distribution can be controlled more precisely throughout the nozzle. The Blue Flow technology allows a more compact hot runner design, meaning the mould can be smaller and more compressed and smaller injection moulding machines with a suitably adjusted output can be used. Production not only becomes more flexible but also more energy efficient, which obviously pleases all injection moulding processors who find sustainability and energy savings a priority.

Marco Kwiatkowski, fully authorized officer and responsible for Günther’s Thick Film Department, explains the advantages of precision for heat distribution: “Power can virtually be distributed precisely down to the millimeter with the new thick-film heaters, thus providing much more uniform heating and, consequently, better plastic mass preparation. This means power can be highly concentrated in the front nozzle section, for example, resulting in lower temperature peaks and producing a higher quality molten plastic.”

Thanks to the thick film technology, the heat conductors and, consequently, the heater itself can also be brought even closer to the plastic melts being processed. Even the power distribution across the entire heating tube can be designed much more freely and precisely since the conductive paths can be positioned more finely (in width/diameter) and more precisely (distances between the heating coils). The temperature control optimized in this way and the fast response by the Blue Flow hot runner nozzle have a positive effect on energy consumption compared with conventional nozzle heaters. The optimum temperature control reduces cycle times and extends processing options. Sommer notes: “This means the heating and cooling input in the mould is decreased thanks to the smaller cavity spacing. As a result, mould dimensions also become more compact and injection moulding machines can be used with less power. Production becomes more flexible overall and much more energy-efficient.”

By clicking on „Subscribe to Newsletter“ I agree to the processing and use of my data according to the consent form (please expand for details) and accept the Terms of Use. For more information, please see our Privacy Policy.

Naturally, we always handle your personal data responsibly. Any personal data we receive from you is processed in accordance with applicable data protection legislation. For detailed information please see our privacy policy.

I hereby consent to Vogel Communications Group GmbH & Co. KG, Max-Planckstr. 7-9, 97082 Würzburg including any affiliated companies according to §§ 15 et seq. AktG (hereafter: Vogel Communications Group) using my e-mail address to send editorial newsletters. A list of all affiliated companies can be found here

Newsletter content may include all products and services of any companies mentioned above, including for example specialist journals and books, events and fairs as well as event-related products and services, print and digital media offers and services such as additional (editorial) newsletters, raffles, lead campaigns, market research both online and offline, specialist webportals and e-learning offers. In case my personal telephone number has also been collected, it may be used for offers of aforementioned products, for services of the companies mentioned above, and market research purposes.

In case I access protected data on Internet portals of Vogel Communications Group including any affiliated companies according to §§ 15 et seq. AktG, I need to provide further data in order to register for the access to such content. In return for this free access to editorial content, my data may be used in accordance with this consent for the purposes stated here.

I understand that I can revoke my consent at will. My revocation does not change the lawfulness of data processing that was conducted based on my consent leading up to my revocation. One option to declare my revocation is to use the contact form found at https://support.vogel.de. In case I no longer wish to receive certain newsletters, I have subscribed to, I can also click on the unsubscribe link included at the end of a newsletter. Further information regarding my right of revocation and the implementation of it as well as the consequences of my revocation can be found in the data protection declaration, section editorial newsletter.

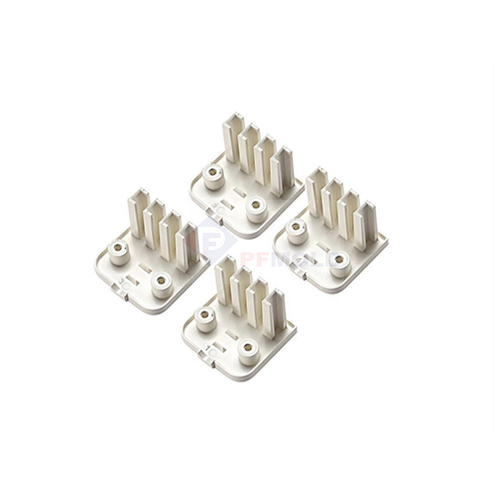

Bergi-Plast is one example of such production processes. A specialist in plastics processing and mould making, the plastics firm based in eastern Germany uses constant analysis of all process steps in injection moulding as the basis for its resource and energy efficiency. The company performed a series of tests to measure the energy consumption levels in three identical 12-cavity moulds to produce what are known as flip tops for tubes. It processed polypropylene (PP) with a shot weight of around 8 grams and a cycle time of twelve seconds. One of the hot runners used was supplied by Günther and was fitted with Blue Flow 4SHF80 nozzles. This Blue Flow technology nozzle achieved an energy saving of 23 percent compared to hot runner technology by other manufacturers.

The material in the thick-film heaters offers a further advantage. For example, conventional nozzle heating technology uses magnesium oxide as electrical insulation around the heating wire carrying the electrical current. Since this material is hygroscopic, i.e. it binds moisture from the surroundings, mostly in the form of water vapor from the humidity in the air, rapid heat-up may cause a short circuit in conventional heater systems. Since the dielectric and conductive layers in thick-film heaters are not hygroscopic and, consequently, do not draw in the moisture, the thick-film heater is prevented from fusing.

To sum up, it can be said that the technical features in Blue Flow technology provide considerable advantages in day-to-day operations for both toolmakers and injection moulding processors. The overall smaller size of the Blue Flow nozzle not only allows narrower cavity spacing but also greater scope for part design. This is why new moulds should be equipped with thick-film heaters or the corresponding Günther nozzle systems from the outset. Older injection moulds should be retrofitted with Blue Flow technology. For the injection moulding processor, the use of smaller injection moulding machines also reduces operating costs and thus also energy consumption.

Incoe Presents its New ‘Heat inject’ Solution for Optimizing Quality of Mould Parts

Oerlikon HRS Flow presented non-cooled hydraulic cylinder at Fakuma 2021

Imprint Cookie-Manager About Media Privacy General Terms and Conditions Help Editors

Copyright © 2023 Vogel Communications Group

Micro Injection Molding This portal is a brand of Vogel Communications Group. You will find our complete range of products and services on www.vogel.com